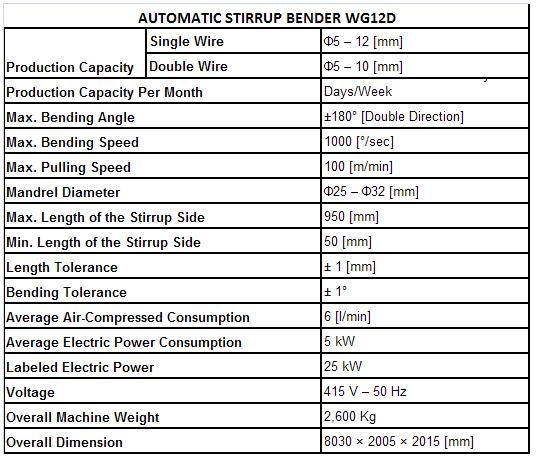

AUTOMATIC STIRRUP BENDER WG12D

- Our Automatic Stirrup Bending Machine is controlled by CNC & worked on Automatic Wire Feeding System. Split, Multi Blade Design (Patented) To Reduce Consumption Costs. Our One Single machine Contains Straightening, Stirrup Bending & Cutting. It can automatically Straighten, Bend and Cut bar wire instead of 20~30 workers & it reduces too much cost.

- It Can Produce 1200~1300 Rings in a hour instead of Using Traditional Method to make Bar Ring where you can only make 1200~1300 Rings in 12 Hour Shift also its Production is too slow.

- Our Automatic Stirrup Production Capacity : 200 Tons 10 Hour Per Day/ 6 Days a week.

- In Today where Construction Companies are timely bound & they have to deliver the project on time Our Automatic Stirrup Machine is right Choice for them.

- Most of Electric Components are Siemens and Schneider Make. Siemens Touchable Screen & Panasonic PLC. Our Stirrup Bender Can Edit any 2D Shapes with Max. 50 Angles, the data base can store more than 500 shapes. Different shapes can be processed continuously without stop, furthermore no need to stop the processing while adjusting the bending angle.

TECHNICAL DATA

Key Features

- Automatic Wire Feeding System (CNC)

- Large Storage Capacity can save 500 Processing Geometric Designs, High Degree Automation

- Production Capacity 200 Tons 10 Hour Per Day/ 6 Days a week

- Siemens Touchable Screen & Panasonic PLC

- Most Electric Components are Siemens and Schneider Make

- Automatic Double Wire intake System

- High Processing efficiency

- High power feeding Servo Motor’s To Ensure Straightening, Bending & Cutting Accuracy

- The Intelligent Fault Identification Alarm System

- Maintenance more Convenient

- Heavy Duty Design Line Planes, Equipped with a Brake and Buffer Device can Prevent Chaotic Lines Caused by Downtime

- High Quality Special Material and High Treatment to make Straightening Wheels, Traction Wheels, The Metering Wheel, Longer Life with Lower Operating Cost

- Touch Screen Console, Easy To Operate and Fast

- Control Systems:- Siemens, Mitsubishi and Yaskawa Schneider Japan

- Can Edit any 2D Shapes with Max. 50 Angles, the data base can store more than 500 shapes. Different shapes can be processed continuously without stop, furthermore no need to stop the processing while adjusting the bending angle

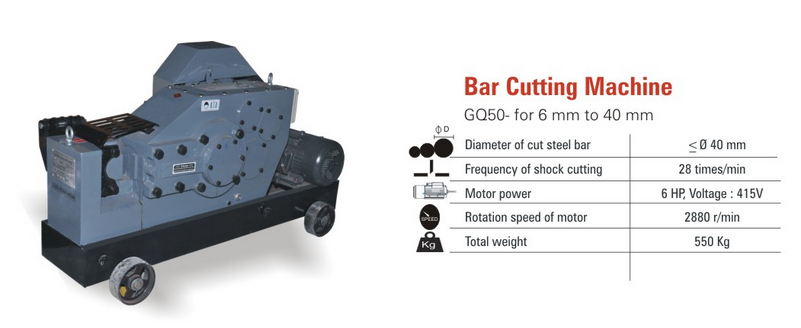

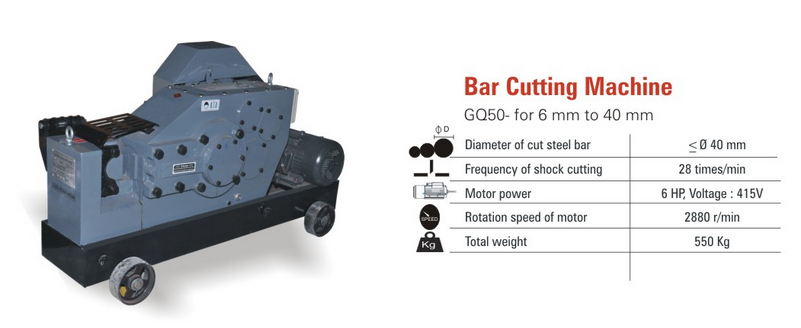

Bar Cutting Machine

It’s body made with high quality cast steel. It is uniquely featured duty gears used or smooth functioning. Clutch system is attached here for safety purpose. The blade used in the machine can be easily replaced and It’s Motor is Pure Copper Winding . This Machine Saves Money and Time for the customer in enormous amount.

Special Features :

- GQ- 50 Best Available Cast Steel Body

- Capacity: 40 mm Dia. Rebar.

- Clutch system is provided for safety purpose.

- Blade can be easily replace.

- Shell/Body of our GQ50 Rebar Cutting Machine is made of Premium raw material cast steel to attain highest standard of the outer shell of the machine. It removes possibilities of loosening bolts during operation. It improves the durability of shell’s life

- Rollers are provided to facilitate transfer of the rebar over top of the machine’s head.

Cutting Blades are covered with the protective metal sheet to provide better safety norms.

Our GQ50 is the best quality produced in India. Our GQ50 can cut 6 mm to 40 mm Rebar all the time & Doesn’t require to adjust the blade while cutting different sizes of the Rebar.

Our GQ50 is Provided with E.L.C.B. & Protective Cover

No skilled required.

No worry about labour.

Saves time and money.

Bar Cutting Machine

Our customers can avail from us Bar Cutting Machine that are available in various models and sizes at market leading prices. All our machines are designed and developed under strict supervision of quality controllers, using premium raw material and latest technology. These products can also be customized as per the demands and requirements of customers.

Our customers can avail from us Bar Cutting Machine that are available in various models and sizes at market leading prices. All our machines are designed and developed under strict supervision of quality controllers, using premium raw material and latest technology. These products can also be customized as per the demands and requirements of customers.

Specifications:

- Capacity: 01 mm to 40 mm

- Motor: 5hp 3Phase & 2800 RPM

- Size: L 1200 mm X W 600 mm X H 700 mm

- Weight: Approx 750 kg

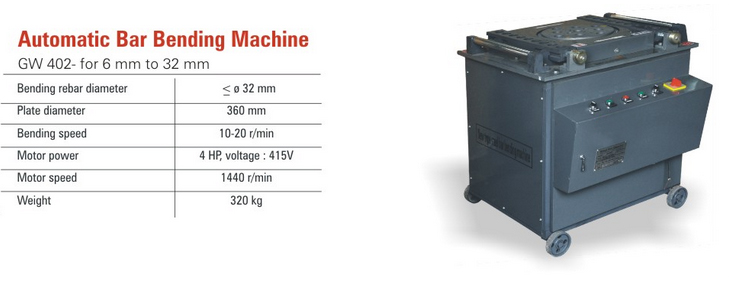

Bar Bending Machine

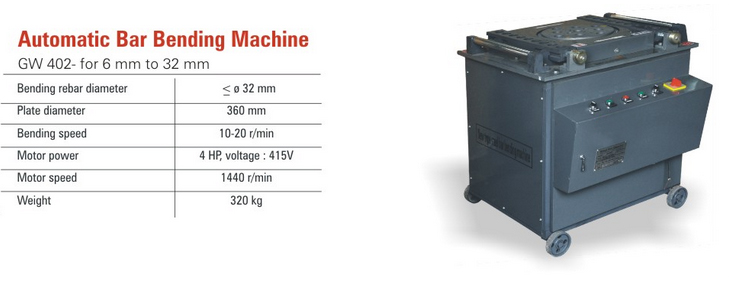

Automatic Bar Bending Machine

GW-42 Steel Bar Bending machines offered by us are designed to bend the bar from 6 m.m. to 32 m.m.

Our fully Automatic Bar Bending Machine are operated through manual button as well as automatic button and deliver stable performance with optimum safety. Further, our machines enable the users to control the path and return it back automatically.

Unlike the traditional steel bar bending machines, our machines are 4-5 times faster. These machines offer perfect bending of small-diameter steel and also serve as a complementary equipment of medium as well as large steel bar bending. GW42 is powered by Havell's Motor wind 3kW/4HP TEFC Induction electric motor running on 3P, 415v with electro-magnetic Brake for instant stop and return.

Features:

- Cost Efficient

- Reduces Manpower

- Reduces Cost

- Save Time Save Money

Bar Bending Machine

For fulfilling the diverse demands of our clients, we provide Bar Bending Machine that are available in various models and sizes. All our machines are manufactured using superior raw material and latest technology to assure flawlessness. Widely demanded by construction industry, our machines are mainly used for bending of reinforcement steel.

Specifications:

- Capacity: 01 mm to 32 mm

- Motor: 7.5hp, 3Phase & 960 RPM

- Size: L 1050 mm X W 950 mm X H 730 mm

- Weight: Approx 550 kg

Scrap Straightening Machine

Scrap Straightening Machine

We offer yet another useful equipment for construction industry. Scrap Bar Straightening Machine is a useful Equipment to Straighten the Scrap Bars to be put to use again. It also has a provision to cut crocked ends of the Bar so that it can be put into the machine easily.

|

Function:

Used to Straighten & Cut Scrap Steel Bar.

Features :

- Optimum Performance

- Easy Operation

- Longer Functional Life

- Low Maintains Cost

|

| MODEL |

MY5-12 |

| Straightening Dia. |

Ø5-Ø12mm |

| Straightening Length |

≥80cm |

| Work Efficiency |

20m/min |

| Reduction Box/Gears |

30:1 |

| Motor Power |

5.5 kW |

| Working Voltage |

415V, 50HZ |

| Net Weight |

265KG |

|

Steel Bar Straightening and Cutting Machine

|

Code : GTQ3-12

Our organization is engaged in manufacturing and trading a wide gamut of Automatically Steel Bar Straightening and Cutting Machines. These machines are developed using quality-examined components and raw material that are sourced from authentic vendors. These machines are acknowledged for their features such as optimum performance, longer functional life and low maintenance cost.

| MODEL |

GTQ3-12 |

| Straightening Diameter |

3-12mm |

| Speed of Straightening |

18-40m/min |

| Motor |

3KW, 380V, 3phase |

|

GTQ4-12 CNC Bar Straightening & Cutting Machine

|

Technical Details:

| MODEL |

GTQ3-12 |

| Straightening diameter |

4-12mm |

| Straightening speed |

25-35 m/min |

| Revolving speed of main shaft |

680 r/min |

| Power |

7.5KW |

| Gross weight |

350 k.g |

|

Features:

- Can Straightening and Cutting 4- 12mm round bar

- We adopt patent technology and innovate , it can use directly when the power on without any debug.

- Easy operating: highly automatic, only one need without any professional training when the machine works.

- Equipped with automatic counter ,length device. Quantity ,length is flexible to change.

- The function of straightening and cutting is stable and safe. Reasonable structure, easy maintenance, accurate length, reliable performance and continuous working.

- Low vibration and voice, convenient adjusting.

- The Bar will be smoothly after straightening , high efficient.

- Suitable for straightening and cutting working of 4-12mm round steel and 4 -10mm deformed steel, automatic CNC operation with high accuracy and working efficiency. Especially suitable for building sites and rebar processing factory.

Concrete Mixer

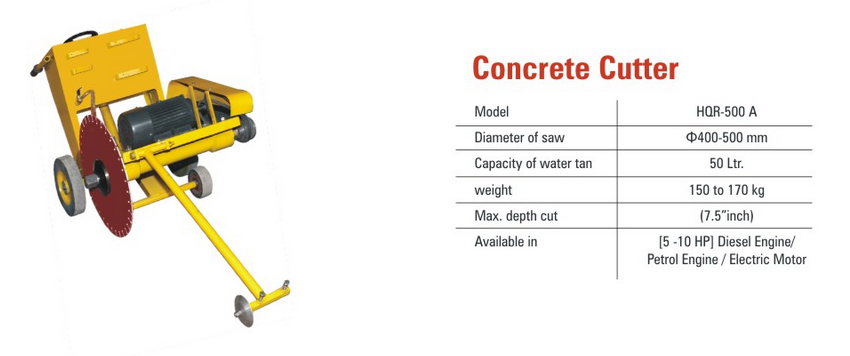

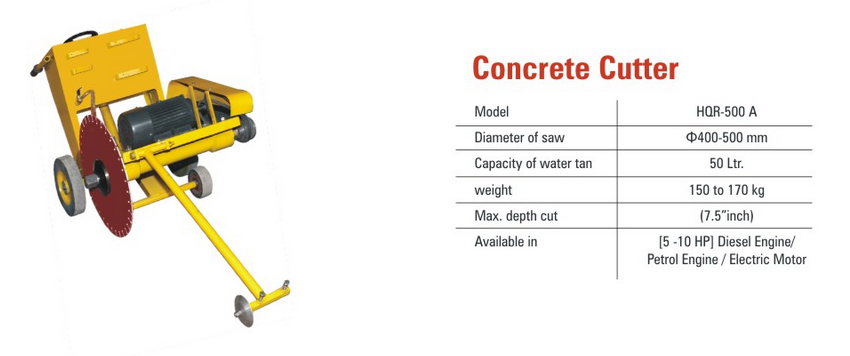

Concrete Cutter

Concrete Cutter

|

|

With the help of our sincere professionals, we are able to bring forth an array of Concrete Cutter.

These are manufactured using quality approved raw material by the experienced engineers of our organization.

We follow international industry guidelines and parameters while manufacturing our products. Available in varied shapes and sizes, these can be offered in customized range to meet the diverse requirements of our clients.

Features :

- Available In Diesel Engine/ Petrol Engine/ Electric Motor

- Enhanced performance

- Low operational cost

- Highly durable

- Technical Chart You Already Have

|

Tamping Rammer

Rammer with Electric Motor

|

Main technical parameters:

| Ramming Frequency |

420-650 times/min |

| Advance Speed |

10-13m/min |

| Leap Height |

40-65mm |

| Motor Power |

4HP Motor |

| Voltage |

415V |

| Rotation speed of motor |

2880r/min |

| Total weight |

70kg |

| Overall Dimension |

700×400×800(mm) |

|

| |

|

Rammer with Diesel Engine

|

Main technical parameters:

| Ramming Frequency |

600-700times/min |

| Advance Speed |

10-13m/min |

| Bounce Height |

45-70mm |

| Motor Power |

5.5HP |

| Voltage |

415V |

| Rotation speed of motor |

2880r/min |

| Total weight |

90kg |

|

Vibrating Plate Compactor/Earth Compactor

Vibrating Plate Compactor/Earth Compactor

We are engaged in designing and developing Vibrating Plate Compactor that meets with international quality norms & standards. All our products are designed and developed using superior raw material and latest machinery that are sourced from the reliable vendors of the market. In addition to this, we have the capability to customize all the products as per the specifications laid down by the customers.

|

Features

- High tensile strength

- Immaculate performance

- Less fuel consumption

Main technical parameters:

| Capacity |

1.5 to 2 ton |

| Power |

3 H.P 3Phase electric motor or 'Greaves' diesel engine |

| Plate Size |

10mm Thickness |

| Weight |

120 Kg. approx. (without prime mover) |

|

Power Trowel

Code : DMR600

Owing to our experience, we have been successful in catering to the requirements of our esteem clients by offering Power Trowel. This range is manufactured by our proficient engineers, in compliance with the set industry standards and guidelines. In addition to this, these products are designed by making use of high-grade raw material, obtained from authentic vendors.

|

| Model |

DMR600 |

| Diameter |

600 mm |

| Speed |

120r/min(R.P.M) |

| QTY of Blade |

4 pcs |

| Blade Size |

230×120mm |

| Net Weight |

75 KG |

|

Code : DMD - 800

|

| Model |

DMR - 800 |

| Diameter |

800mm |

| Speed |

120r/min(R.P.M) |

| QTY of Blade |

4 pcs |

| Power |

2.2KW/380V/50HZ |

| Blade Size |

290×120mm |

| Net Weight |

85 KG |

|

Code : DMD - 900

|

| Model |

DMD - 900 |

| Diameter |

900mm |

| Speed |

66~132(R.P.M) |

| QTY of Blade |

4 pcs |

| Power |

2.2KW/380V/50HZ |

| Blade Size |

345×150mm |

| Net Weight |

98kg/116kg |

|

Walk Behind Vibrator Rollers

Walk Behind Vibrator Rollers

With the help of our skilled engineers, we are able to offer a wide array of Mini Vibro Rollers. All our products are products are available in varied grades, dimensions and specifications to match the needs of customers. The products we are offering are acknowledged for their reliability, optimum performance, low maintenance cost and easy operations. Further, we ensure that only defect-free rollers are delivered at patrons' premises.

|

| Weight (kg) |

740 |

| Vibratory Frequency (times/min) |

3600 |

| Centrifugal Force (kn) |

24 |

| Max Travelling Speed (km/h) |

2.5 |

| Gradeability (%) |

20 |

| Water Tank Capacity (l) |

35 |

| Fuel Tand Capacity (l) |

25 |

| Vibratory Wheel Width (cm) |

65 |

|

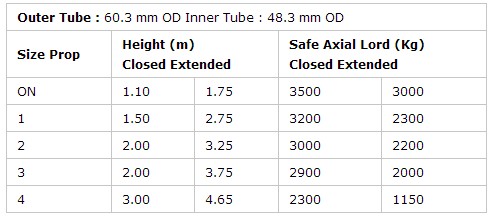

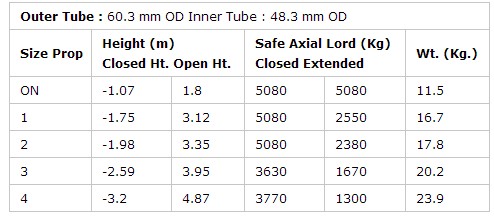

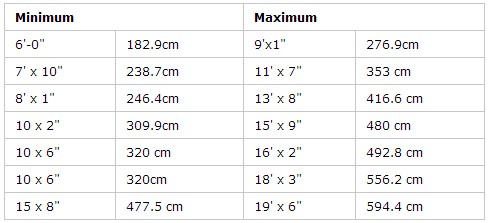

Suspended Platform

Suspended Platform

We are supplying and manufacturing Suspended Platform, Gandola System, Aerial Platform, Hanging Platform, Working Platform or Steel/ Aluminum Suspended Platform. A kind of Temporarily Installed Suspended Access Equipment, also known as Suspended Platform or Temporary Access Equipment, is a lightweight aluminum-made object capable of carrying persons onto a certain height so as to facilitate the aerial work, such as maintenance, decoration, cleaning, etc. It is easy for operation, flexible for moving, reliable in safety. Besides, it is not necessary to build scaffolding in the construction, the efficiency will be promoted and the cost will be reduced.

| MODEL |

ZLP800 |

| Platform size |

2.5mts x 3 |

| Material of platform |

Steel Platform- Hot Galvanized |

| Balance Weight |

1000kgs. |

| Rated load |

800kgs. |

| Ascend Speed (working speed) |

9-11m/min |

| Wire rope |

4x31 Sw –FC- 9.1 |

| Rated Lifting force |

5KN |

|

ELECTRIC MOTOR

| Power |

1.8kWx 2 |

| Voltage |

AC 415v 3 phase |

| Breaking |

15 NM |

| Safety lock |

Tilt proof safety lock (2 No.s) |

|

SUSPENED MECHANISM

| Height Adjustment |

1.15m – 1.75m |

| Front Beam extension |

1.1m – 1.7m |

|

Features :

- Durable

- Trouble-free operation

- Corrosion resistance.

- easy for operation

- flexible for moving

- reliable in safety

To ensure safe operation without danger to personnel, all the platform are fitted with the following safety devices:

- Service brake incorporated in the hoist.

- Two fall arrest devices acting on the safety wire ropes.

- Two upper limit switches.

- No power descent in case of power failure.

- Anti-tilt device.

- Emergency stop.

- Phase controller.

Rebar Threading Machine

Prominent & Leading Supplier and Distributor from New Delhi, we offer Rebar Threading Machine such as Rebar Threading Machine- Fully Automatic and Rebar Threading Machine- Semi Automatic ( Manual).

Rebar Threading Machine- Fully Automatic

|

| Specification |

Value |

| Rebar Diameter |

16 To 40mm |

| Motor Power |

4kW/6 H.P. |

| Electricity |

415V 50HZ |

| SPEED |

40-62r/min |

| Main shaft speed |

80mm |

| Thread Pitch |

3.5 |

| Net Weight |

550kg |

|

The machine is mainly used of rebar in Construction projects, being key equipment to thread and join the rebar to gain length.

Main Characteristic:

- Very High on Production, Saves lot of time & replacing blades need only 5 minutes

- Equipped automatic opening & closing structure, one time caliper rebar then finish working at the 30 seconds.

- Roll stamping thread after steel bar rib peeling, with good shape of thread, high precision and conformed diameter size

- Processing parallel thread for ribbed rebar 16mm - 40mm

- Rolling wheel has long service period, low additive cost of connector

- Easy to adjust for rolling steel bars in different specifications, adjustment can be made without loosing rolling head, with same given screw distances.

Rebar Threading Machine- Semi Automatic ( Manual)

|

| Specification |

Value |

| Rebar Diameter |

16 To 40mm |

| Motor Power |

4kW/6 H.P. |

| Electricity |

415V 50HZ |

| SPEED |

40-62r/min |

| Main shaft speed |

80mm |

| Thread Pitch |

3.5 |

| Net Weight |

450kg |

|

Main Characteristic:

- Very High on Production, Saves lot of time & replacing blades need only 5 minutes

- Roll stamping thread after steel bar rib peeling, with good shape of thread, high precision and conformed diameter size

- Processing parallel thread for ribbed rebar 16mm to 40mm

- Rolling wheel has long service period, low additive cost of connector

- Easy to adjust for rolling steel bars in different specifications, adjustment can be made without loosing rolling head, with same given screw distances

Sand Screening Machine

Sand Screening Machine

|

We are engaged in providing our clients with Sand Screening Machine that are manufactured using superior raw material and latest technology. All our machines are available in various models and sizes at market leading prices. Apart from this, we provide tailor-made solution for all the products as per the demands and needs of customers.

Features:

- Easy operations

- Lightweight

- Optimum performance

- Low maintenance

|

Construction Hoists

Electric Mini Hoist

|

Electric Mini Hoist is small, light, easy disassembly and assembly.

Technical Specification :

| Moment |

2m from the front base |

| Rated Loading Capacity |

800kg |

| Max. Lifting Load |

1000kg |

| Max. Lifting Height |

20m - 25m |

| Motor power |

3KW/415V/50HZ/3phase |

| Motor front/back power |

1KW/415V/50HZ/3phase |

|

Monkey Hoist

|

Monkey hoister is small, light, easy to disassemble and assemble.

Its specification as follow :

| Rotation |

360 Degree |

| Rope length |

50m |

| Maximum lifting height: |

45m |

| Maximum lifting capacity |

500Kg |

| With Remote operations for working |

|

Jib Crane

|

We are offering a qualitative assortment of Jib Crane With Bucket. Our product range is manufactured using premium quality raw material and the latest techniques in compliance with the international standards. These machines are well-known among our clients for their dimensional exactness, excellent performance and trouble-free functionality. Furthermore, clients can avail these buckets from us in various capacities and models. We offer these machines at very reasonable prices.

Specifications :

| Jib Working |

7.5 Feet |

| Load Capacity |

500 Kg |

| Movement |

360 degree |

| Motor |

7.5H.P |

| Bucket |

One |

| Wire Rope |

70 Meter |

|

Concrete Vibrators

High Frequency Vibrators

Code : ZEB200-68-4

Electronic Frequency converter 3 phase with 4 outlets. Used to attain consolidation in the concrete, suitable for low sump concrete and for long hour usage, very low maintenance, low noise and utmost durable.

|

Specification :

| Capacity |

6.8kVA |

| Input |

ph/hz/v /A 3/50/380-440/5.9 |

| Output |

ph/hz/v/A3/200/48/79 |

| Weight |

50KG |

| No. of Outlets |

4 x 65mm |

|

High Frequency Single Phase Vibrators

Code : VH Series

High frequency vibrators with integrated portable inverter to be run on single phase 220V

|

| Technical Data |

VH40 |

VH50 |

VH60 |

| Head diameter(mm) |

41 |

51 |

60 |

| Head length(mm) |

335 |

375 |

420 |

| Head weight(kg) |

2.8 |

4.3 |

7.2 |

| Input voltage(V) |

220-250 |

220-250 |

220-250 |

| Input phase(Ø) |

1 |

1 |

1 |

| Input frequency(Hz) |

50 |

50 |

50 |

| Output voltage(V) |

110 |

110 |

110 |

| Output phase(Ø) |

3 |

3 |

3 |

| Output frequency(Hz) |

200 |

200 |

200 |

| Output current(A) |

2.9 |

4.8 |

7.0 |

|

High Speed Vibrators

Code : SHSD 25

We manufacture a wide range of vibrator machines that are manufactured using qualitative material sourced from trusted vendors. These machines find extensive application in various industries and have gained tremendous appreciation in the market. Available in various specifications, these machines can also be customized as per the specifications detailed by the clients. Very high performing vibrators, best feature is portability.

The high speed vibrators / drive we manufacture have gained huge appreciation in the market for their host of qualitative features. These are available in the following models

|

| Model |

Diameter (mm) |

Length (mm) |

Vibrating Amplitude (mm) |

Rubber Length |

| SHSV 29-3 |

29 |

337 |

0.81 |

3m |

| SHSV 39-3 |

39 |

318 |

0.77 |

3m |

| SHSV 49-3 |

49 |

318 |

0.7 |

3m |

| SHSV 59-3 |

59 |

318 |

0.7 |

3m |

| Model |

- |

SHSD 25 |

| Power |

(kW) |

1.6 |

| Power Source |

- |

220 V ~ 50 / 60 Hz |

| Current |

(A) |

11 |

| No-Load Speed |

(rpm) |

18000 |

| Overall Dimension L x W x H |

(mm) |

340 x 190 x 190 |

| Total Weight |

(kg) |

7.5 |

|

Shutter Vibrator

We are one of the most prominent Power Shutter Vibrator Manufacturers, based in India. The technically sturdy Shutter Vibrator available with us is extremely efficient for several industrial purposes. The superior Industrial Shutter Vibrator served by us consists of quality features such as corrosion resistance, precise length, weight, and diameter, etc.

|

Technical Specifications :

| Model No. |

(rpm) |

(Kgf) |

(V) |

(A) |

(HP) |

| SV 2 |

2840 |

200 |

415 |

1.1 |

0.5 |

| SV 3.5 |

2840 |

350 |

415 |

1.9 |

1 |

| SV 7 (Small) |

2840 |

600 |

415 |

2.8 |

1.5 |

| SV 7 (Big) |

2840 |

700 |

415 |

3.24 |

2 |

| SV 9 |

2840 |

900 |

415 |

6 |

3 |

|

Concrete Vibrator

|

We provide a wide range of Concrete Vibratory Accessories that are made out of superior quality raw materials. Our Concrete Vibrator Accessories posses’ high tensile strength and efficiency. We manufacture this product with the specification of our clients.

|

Block Machines

Creating a niche of Block Machines such as Manual Vibrators Block Machine and Egg Laying Block Machine at its best, with utmost quality.

Manual Vibrators Block Machine

|

We are instrumental in offering our clients with Manual Vibrator Block Machine that are available in different models. Ideal for construction purposes, our machines are designed in strict compliance with international quality standards & norms. In addition to this, we provide customization as per the specifications laid down by the customers.

Salient features of our range are as follows:

- Excellent performance

- Easy installation

- Low maintenance

- Longer service life

|

Egg Laying Block Machine

|

Specifications:

- Pump Motor : 3 HP

- Vibratory Motor : 1HP /2 HP-2800RPM

- Moving Motor : 1 HP

- Mould Area : 857mm x 640mm

|

Testing Equipment

We present to our clients a wide assortment of Testing Equipment that are extensively used in various laboratory experiments. These Testing Equipment are known for their precision and accuracy, we offer them to our clients at competitive prices.

Cube Mould

|

We are engaged in manufacture and supply of various construction equipments including Cube Mould. We use the finest quality cast iron to manufacture this and offer in various sizes to our esteemed clients. These are offered to our valued clients at leading industry rates.

Features:

- Sturdy design

- Flawless finish

|

Concrete Testing Machine

|

We bring forth for our clients Concrete Testing Machine that are available in different models at market leading prices. All the machines are designed and developed in such a way that assure these meet with international quality norms & standards. These machines can also be customized as per the demands and requirements of customers.

Features:

- Longer functional life

- Sturdy construction

- Low maintenance

- Easy handling

|

Slum Cone

Our customers can avail from us Bar Cutting Machine that are available in various models and sizes at market leading prices. All our machines are designed and developed under strict supervision of quality controllers, using premium raw material and latest technology. These products can also be customized as per the demands and requirements of customers.

Our customers can avail from us Bar Cutting Machine that are available in various models and sizes at market leading prices. All our machines are designed and developed under strict supervision of quality controllers, using premium raw material and latest technology. These products can also be customized as per the demands and requirements of customers.